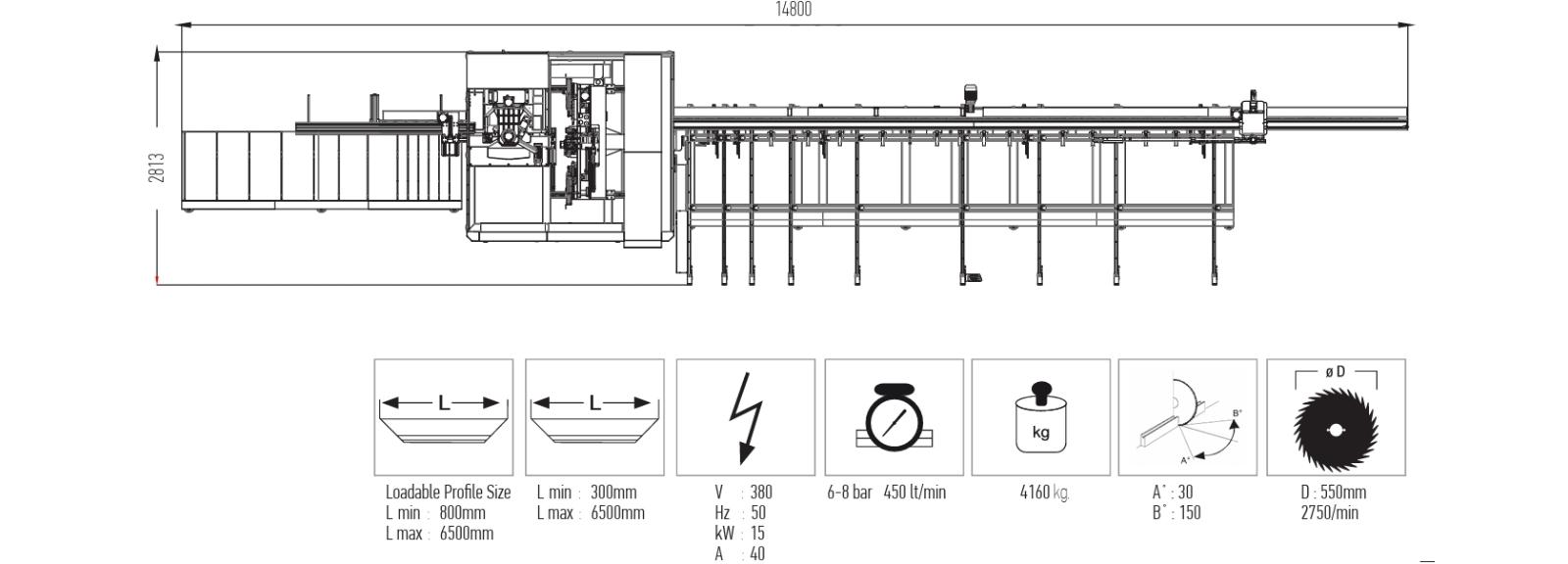

SC/231 OL PVC PROFILE PROCESSING AND CUTTING CENTER

GeneralInformation

Compatible with all type of PVC profiles and optimization programms.

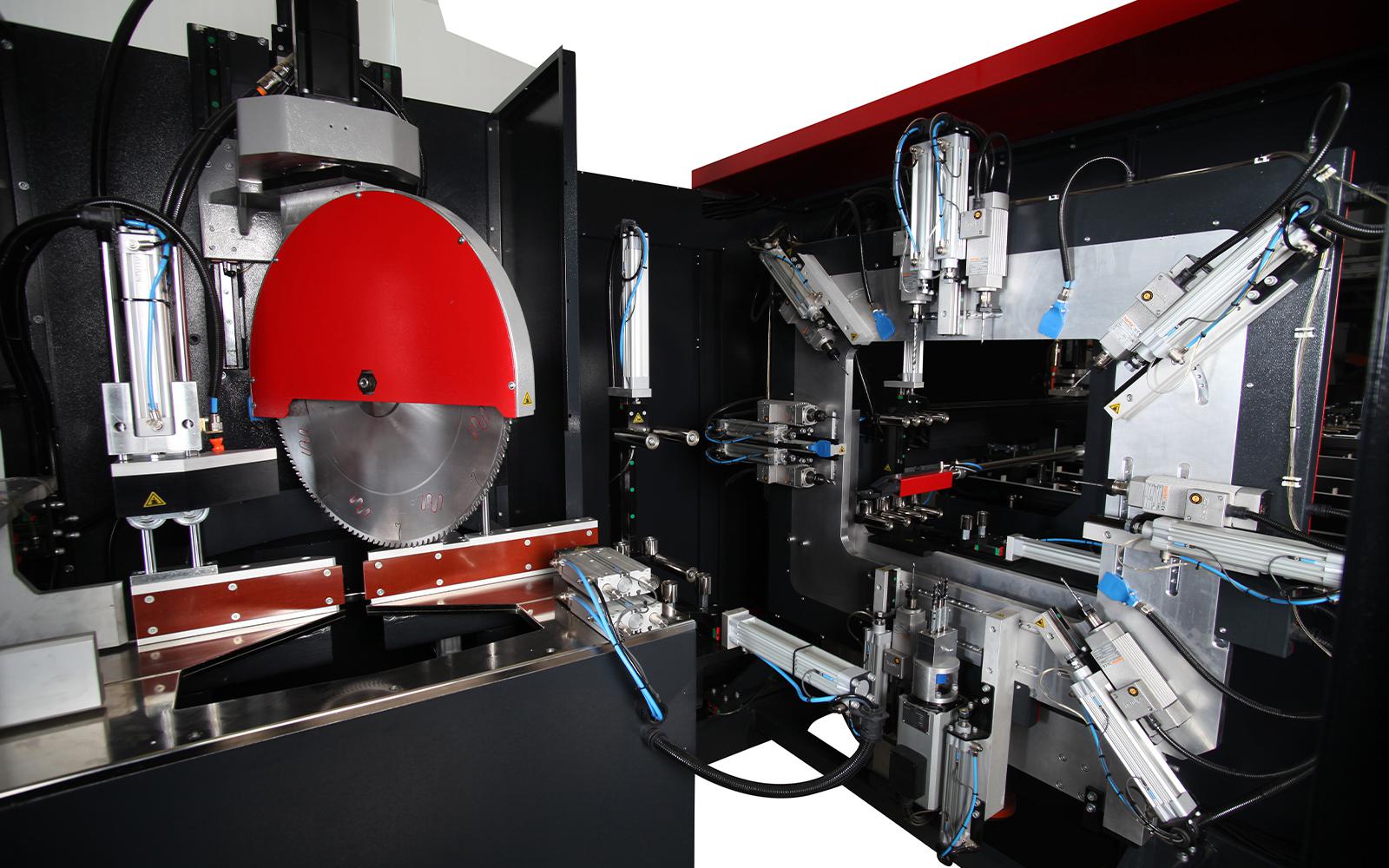

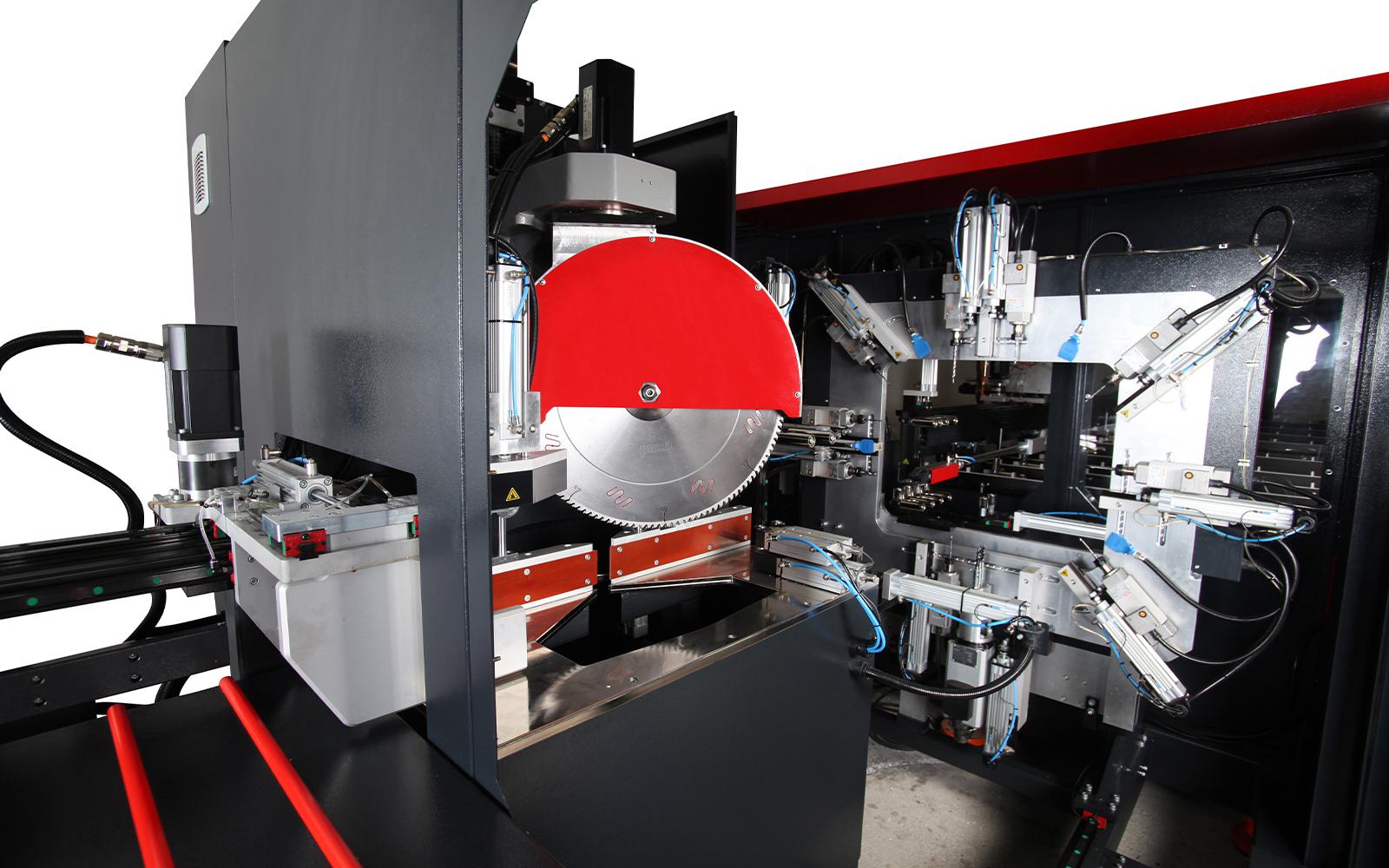

Center has a 3-axis servo motor controlled CNC processing unit that allows all operations such as grooving, drilling, marking, berrel and handle hole opening on four surfaces on the profile to be performed by adhering to the desired parametres.

The milling unit opens the door handle and cylinder holes in one operation, providing minimum machining time.

Triple handle hole drilling process made in one move, provides minimal processing time.

High capacity possibility by performing cutting process and milling operations working at same time synchronously.

It provides minimum processing time by grooving the door lock and espagnolette chanel in one operation.

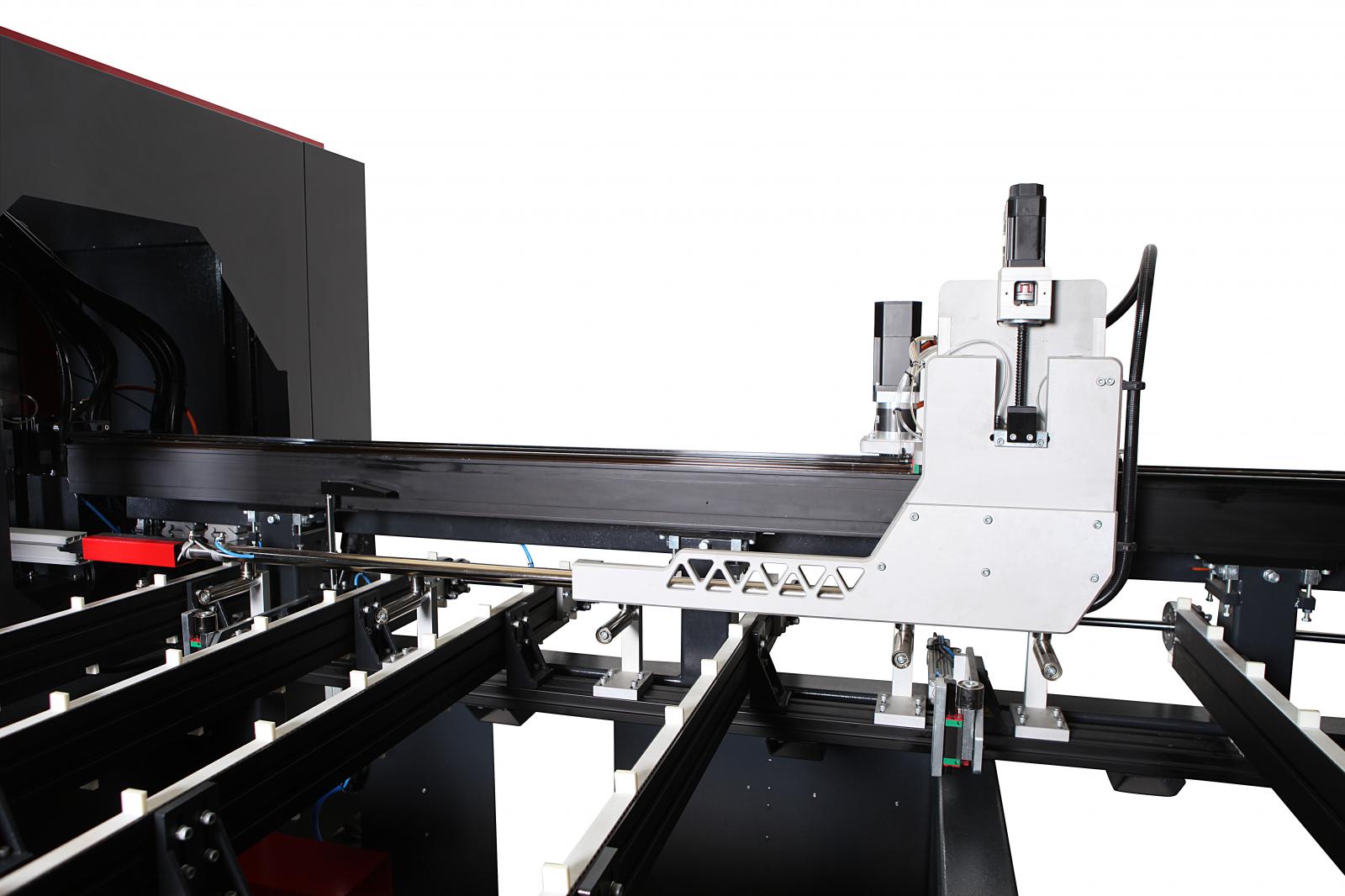

Profile loading losses are minimized by moving independently of robot arm holder and profile loading station.

The holding arm has the possibility of movement in 3 axes.

Automatic profile capturing system.

Automatic profile length detection feature.

Profile feeding unit can be loaded with profiles of desired length in the range of 800 mm - 6500 mm.

Remote connection support. 15,6’ high performance industrial Touchscreen PC (“Perfection in Automation Made in Austria B&R”) 10 high-speed special air-cooled spindles.

Servo controlled cutting unit providing 0.1⁰ precision cutting between 30⁰-150⁰. Transportation of cut waste profiles to the collection car with the automatic conveyor system.

Servo motor system for quick discharge after profile cutting.

Saw up and down servo control system for fast cutting.

OPTIONS

Absorber unit